Morung Express News

Dimapur | July 10

With an increasing number of the state’s populace moving away from rural and traditional livelihoods, and moving into urban space, a need to enable such populace to blend in to the new and challenging surroundings has arisen.

And with the number of unemployed youths increasing in number by the day, an institute in Dimapur has taken up the task to train youths, providing them with an opportunity to learn skills with viable livelihood opportunities suited to their needs.

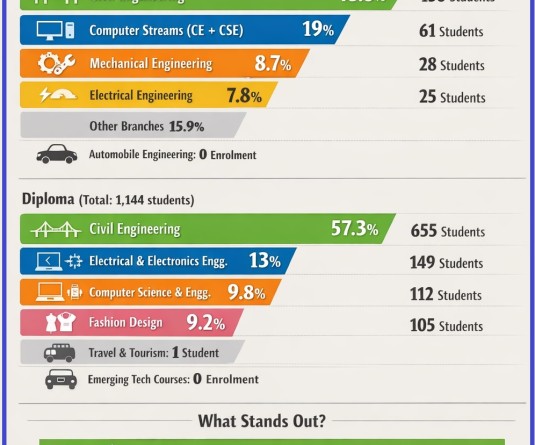

The Nagaland Tool Room & Training Centre offers an array of diploma and certificate courses with the duration ranging from 1 month to four years.

Toolmakers

A Tool Room is the industrial set-up (common facility centre) where specialized Tools, Dies, Moulds, Jigs, Fixture are designed and manufactured. These tools are used for mass production for all Plastic components, Aluminum or any casting parts from kitchen utensils to space components, automotive, agriculture & industrial components, etc.

The institute currently has around 300 students learning how to make production tools and equipments. Principal of NTTC, Er. Petehetuo Miasalhou beams with pride while referring to his students as “Toolmakers”.

“We are able to help our Naga innovators in bringing out new kinds of machines,” he says explaining that the institute trains students to design and develop new innovative technology e.g. bamboo processing, stone processing while also providing other skill development courses e.g. Steel fabrication, automobile technician, machine operators, fitters, computer courses etc.

Inside the Training Centre, students bustle with life as they work enthusiastically on the buzzing and roaring machines. Some use hammers, saw and other tools trying to punch holes and smooth edges.

A look inside the machine rooms reveal state of the art machines including Computer Aided Design & Manufacturing software (CAD/CAM), CNC Millings, CNC EDM, CNC WEDM, Jig Grinding, Injection Moulding Machines, Heat Treatment Units, conventional shop floor machines like drilling machines, surface grinding, cylindrical grinding, lathe machines, milling machines, welding machines, etc.

Imliyanger Chang is in his final year of the 4 years Diploma in Tool & Die Making Course. Keenly interested in anything mechanical, Yanger, as he is known by his friends, joined the institute after his matriculation. Currently working on orders from local customers which the institute received, Yanger wants to pursue further studies. The four year diploma course will enable him to take up B.Tech.

Anant Kumar (21) from Bihar got to hear of NTTC through a friend and signed up for the Tool & Die course. Kumar, who is also in his final year, along with his batch-mates were sent to Pune for hands-on training as part of the course. In Pune, he interned at Vishal Engineering Company, a company dealing in vehichle parts. “It has been a good experience so far,” he says confident that he will be able to make any vehicle part today.

Established in 2006 by the Government of Nagaland in partnership with the Ministry of Micro, Small and Medium Enterprise (MSME), the institute is registered as a quasi-government body under the Directorate of industries & Commerce.

NTTC is an AICTE approved institute and is recognized by the Ministry of Labour and Employment, Government of India. The second Tool-room Training institute in the North East, NTTC has roughly trained about 2000 students so far out of which, about 600 have been placed in various companies across the country.

Courses

NTTC offers long term courses including Diploma in Tool & Die (3+1 years). This course, Principal Er. Miasalhou informs, is meant for big manufacturing companies. “They are useful there. Demand is also there,” he says. “They have to go outside the state for the immediate.”

Short term courses include welding fabrication, machinist course, electrician, computer hardware and networking etc. “These students can remain in the state and be the workforce for the state,” Er. Miasalhou opines.

Lack of fund

“For manufacturing a product, it requires different processes. We do not have all the machines,” Er. Miasalhou says. He also laments the lack of manpower. “There is a need for more manpower to run machines 24/7,” he says pointing to the high precision CNC machines. However, he is hopeful that the institute will play an important role in training youth in the industrial sector.

Plastic processing

Plastic processing is one sector which can provide lots of job avenues to the youth and also contribute to the state’s economy. NTTC aims to start courses in Plastic Processing by the beginning of next year. Around the same time, the institute also aims to procure plastic processing machines so that the institute can also function as the sole plastic processing plant in Nagaland. “Students after completion of the course can also get a job and produce,” Principal Er. Miasalhou says.